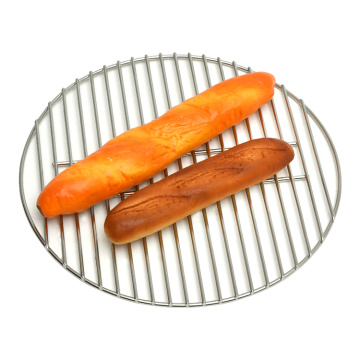

Shenzhen Lanejoy Technology Co.,LTD

Lanqiaoying Technology Co., LTD was established in 2009. As of 2017, it has 5 subsidiaries. Shenzhen Lanqiaoying Technology Co., Ltd is an industry-leading manufacturer with registered funds 10 million RMB, specializing in the fields of precision hardware, copper nut, spring, kitchen ware, kitchen products, stainless steel products, and professional metal surface treatment. Lanejoy is a company integrating design, manufacturing and sales. It is committed to promoting simple, practical and...